CBD (cannabidiol) has gained significant popularity for its potential health benefits without psychoactive effects. But have you ever wondered how this compound makes its journey from the cannabis plant to the bottle of oil in your medicine cabinet? The transformation from plant material to usable CBD oil involves specific scientific processes designed to isolate and preserve the beneficial compounds.

This comprehensive guide explores the various extraction methods used by manufacturers to produce CBD oil, the science behind each technique, and what factors determine product quality. Whether you’re a curious consumer or considering CBD production, this article provides valuable insights into how CBD oil is made.

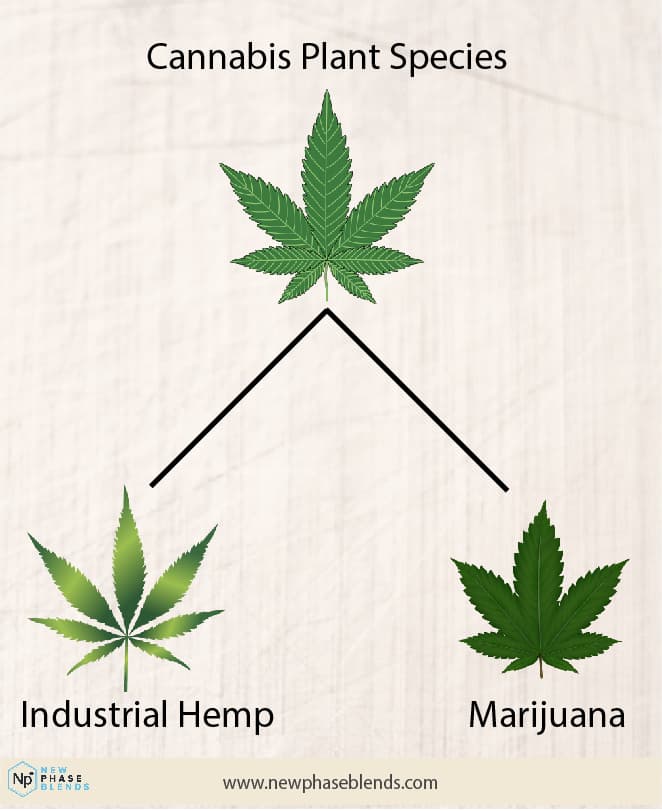

The Source Matters: Hemp vs. Marijuana

Before discussing extraction, it’s essential to understand the source material. CBD can be extracted from both hemp and marijuana plants, which are different varieties of the Cannabis sativa species.

Legal Considerations and THC Content

Hemp-derived CBD is federally legal in the United States under the 2018 Farm Bill, provided it contains less than 0.3% THC (tetrahydrocannabinol). This trace amount is insufficient to produce psychoactive effects, making hemp-derived CBD non-intoxicating.

Marijuana-derived CBD typically contains higher THC levels and remains federally regulated, though legal status varies by state. For this article, we’ll focus primarily on hemp-derived CBD oil production, which represents the majority of the commercial market.

Cannabinoid Profiles

Hemp plants are specifically cultivated to maximize CBD content while maintaining minimal THC levels. Different cannabis strains contain varying cannabinoid profiles, which ultimately influence the composition of the extracted oil. Premium CBD products often begin with selectively bred, high-CBD hemp strains grown under controlled conditions.

CBD Extraction Methods: A Comparative Analysis

Several extraction methods exist for isolating CBD from hemp plant material. Each approach offers distinct advantages and challenges regarding safety, efficiency, purity, and scalability.

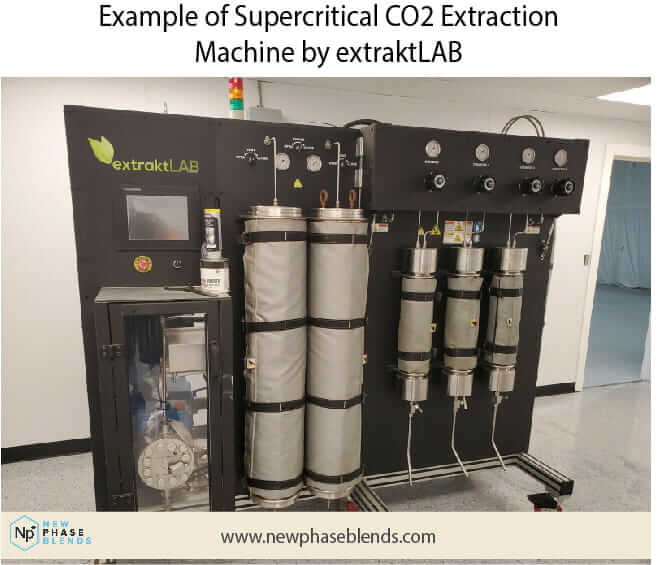

1. CO₂ Extraction Method (Supercritical Fluid Extraction)

The Process: CO₂ extraction utilizes carbon dioxide in a supercritical state—exhibiting properties of both liquid and gas—to act as a solvent. This process occurs in a closed-loop extraction system with multiple chambers:

- The first chamber contains frozen CO₂ (dry ice)

- The second chamber holds the prepared hemp material

- Additional chambers facilitate separation and collection

When CO₂ transitions to its supercritical state (through precise temperature and pressure controls), it passes through the plant material, dissolving the cannabinoids and terpenes. The solution then moves to separate chambers where pressure changes cause the CO₂ to return to gas form, leaving behind the extracted compounds.

Advantages:

- Produces exceptionally pure extracts with minimal contamination

- Allows for precise tuning to target specific compounds

- Leaves no toxic residual solvents

- Preserves temperature-sensitive terpenes and cannabinoids

- Environmentally friendly as CO₂ can be recycled in the closed-loop system

Limitations:

- Requires sophisticated equipment with significant initial investment

- Technical expertise needed for proper operation

- Higher production costs that may be reflected in product pricing

2. Ethanol/Alcohol Extraction

The Process: Ethanol extraction involves soaking hemp plant material in high-grade grain alcohol, which dissolves the cannabinoids and other plant compounds. After sufficient extraction time, the plant material is removed, and the ethanol is evaporated, leaving behind a concentrated extract.

The process typically follows these steps:

- Plant material is soaked in ethanol, often at specific temperatures

- The solution is filtered to remove plant material

- Ethanol is removed through evaporation/distillation

- The resulting extract undergoes further refinement

Advantages:

- Efficient at extracting a full spectrum of cannabinoids and terpenes

- Generally regarded as safe (GRAS) by the FDA when properly removed

- Relatively simple process with lower equipment costs than CO₂

- Suitable for large-scale production

Limitations:

- May extract water-soluble compounds like chlorophyll, requiring additional filtration

- Potential for residual solvent contamination if evaporation is incomplete

- Flammability poses safety concerns requiring proper facilities

3. Olive Oil Extraction Method

The Process: The olive oil method represents one of the oldest and simplest extraction techniques, making it accessible for small-scale or home production:

- Hemp material is decarboxylated (heated) to activate cannabinoids

- The activated material is then heated in olive oil, allowing cannabinoids to infuse

- The plant material is strained, leaving cannabinoid-enriched oil

Advantages:

- Exceptionally safe with no risk of toxic residue

- Beginner-friendly with minimal equipment requirements

- Preserves terpenes and multiple cannabinoids for entourage effect

- Avoids harsh chemicals or complicated procedures

Limitations:

- Produces relatively low-concentration extracts

- Limited shelf life compared to other methods

- Not commercially viable for large-scale production

- Cannot create highly concentrated products

4. Hydrocarbon Extraction (Butane/Propane)

The Process: Hydrocarbon extraction uses solvents like butane or propane to strip cannabinoids from plant material:

- Chilled solvent passes through plant material in a closed-loop system

- The solution collects in a separate container

- Solvent is purged through heating under vacuum

- Resulting extract is further refined as needed

Advantages:

- Efficiently extracts cannabinoids and terpenes

- Can produce high-potency concentrates

- Relatively fast process with good yields

Limitations:

- Significant safety concerns due to flammability

- Requires professional equipment and safety measures

- Risk of residual solvents in final product

- Environmental considerations regarding hydrocarbon use

The Refinement Process: From Crude Extract to Final Product

Extraction is only the first step in CBD oil production. The crude extract must undergo several refinement processes to create a clean, potent, and consistent product.

Winterization

Winterization removes undesirable substances like waxes, lipids, and chlorophyll from the crude extract. The process involves:

- Mixing the extract with ethanol

- Freezing the solution to solidify fats and waxes

- Filtering out the solidified materials

- Removing the ethanol through evaporation

Decarboxylation

Raw hemp contains primarily CBDA (cannabidiolic acid), which must be converted to active CBD through decarboxylation. This process involves heating the extract to specific temperatures to remove the carboxylic acid group from CBDA molecules, transforming them into CBD.

Distillation

For higher-purity products, distillation separates compounds based on their boiling points:

- Molecular distillation uses heat and vacuum to separate cannabinoids

- Each compound vaporizes at a different temperature

- The vapor is collected and condensed

- Multiple passes create increasingly pure distillate

Isolation and Crystallization

To produce CBD isolate (99%+ pure CBD), further processing includes:

- Chromatography to separate individual cannabinoids

- Chemical washing to remove impurities

- Crystallization of pure CBD molecules

Product Formulations: From Extract to Marketable CBD Oil

The refined CBD extract must be formulated into consumer products. For CBD oil tinctures, this typically involves:

- Diluting the extract in a carrier oil (MCT coconut oil, hemp seed oil, olive oil)

- Adding terpenes for flavor and enhanced effects (optional)

- Incorporating additional ingredients for specific formulations

- Laboratory testing for potency, purity, and consistency

Spectrum Options

Full-spectrum CBD oil contains all naturally occurring compounds from the hemp plant, including trace THC (below 0.3%).

Broad-spectrum CBD oil maintains multiple cannabinoids and terpenes but removes THC through additional processing.

CBD isolate products contain only pure CBD with no other cannabis compounds.

Quality Control and Testing: Ensuring Safe, Effective Products

Reputable CBD manufacturers implement rigorous quality control measures throughout production:

Third-Party Laboratory Testing

Independent laboratory analysis verifies:

- Cannabinoid profile and potency

- Terpene content

- Absence of residual solvents

- Microbial screening

- Heavy metal testing

- Pesticide screening

Certificate of Analysis (COA)

Quality producers provide Certificates of Analysis for each product batch, documenting test results and confirming product safety and potency.

Small-Scale Production: Making CBD Oil at Home

While commercial production requires sophisticated equipment, small-scale extraction is possible for personal use, particularly using the olive oil method:

- Decarboxylation: Heat ground hemp flower at approximately 240°F (115°C) for 60-90 minutes to activate cannabinoids.

- Infusion: Combine activated hemp with olive oil (typically 1:1 ratio by weight) in a double boiler. Heat gently at 200°F (93°C) for 2-3 hours, stirring occasionally.

- Filtration: Strain the mixture through cheesecloth or fine mesh to remove plant material.

- Storage: Store in a dark glass container away from light and heat.

Important Safety Considerations:

- Always use legally sourced hemp with verified THC content

- Maintain proper ventilation when heating materials

- Keep temperatures controlled to avoid degrading cannabinoids

- Start with small batches until you perfect your technique

- Test your homemade product for potency if possible

The Future of CBD Extraction Technology

The CBD industry continues to evolve with emerging technologies enhancing extraction efficiency and product quality:

- Ultrasonic-assisted extraction uses sound waves to increase extraction efficiency

- Microwave-assisted processing reduces extraction time while preserving compounds

- Enzyme-assisted extraction employs natural enzymes to separate plant components

- Sustainable practices focus on reducing environmental impact and resource consumption

Conclusion: Making Informed Choices About CBD Oil

Understanding how CBD oil is made provides valuable context for evaluating product quality and making informed purchasing decisions. The extraction method significantly impacts the final product’s purity, potency, and chemical profile.

When selecting CBD products, consider:

- Extraction method used (CO₂ generally indicates premium quality)

- Spectrum type (full, broad, or isolate) based on your needs

- Third-party testing verification

- Transparency about sourcing and production methods

- Carrier oil quality and additional ingredients

Whether you’re considering small-scale home production or simply want to understand what goes into your wellness products, knowledge about CBD extraction empowers you to identify quality products in an increasingly crowded marketplace.